17+ Steam Trap Diagram

External strainer ahead of the steam trap b. Web STEAM TRAPS Inverted Bucket Steam Trap Inverted Bucket Conn.

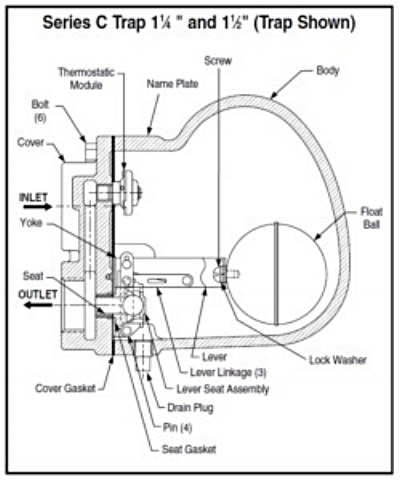

Float Steam Trap Screw End Flanged Adca Flt 17

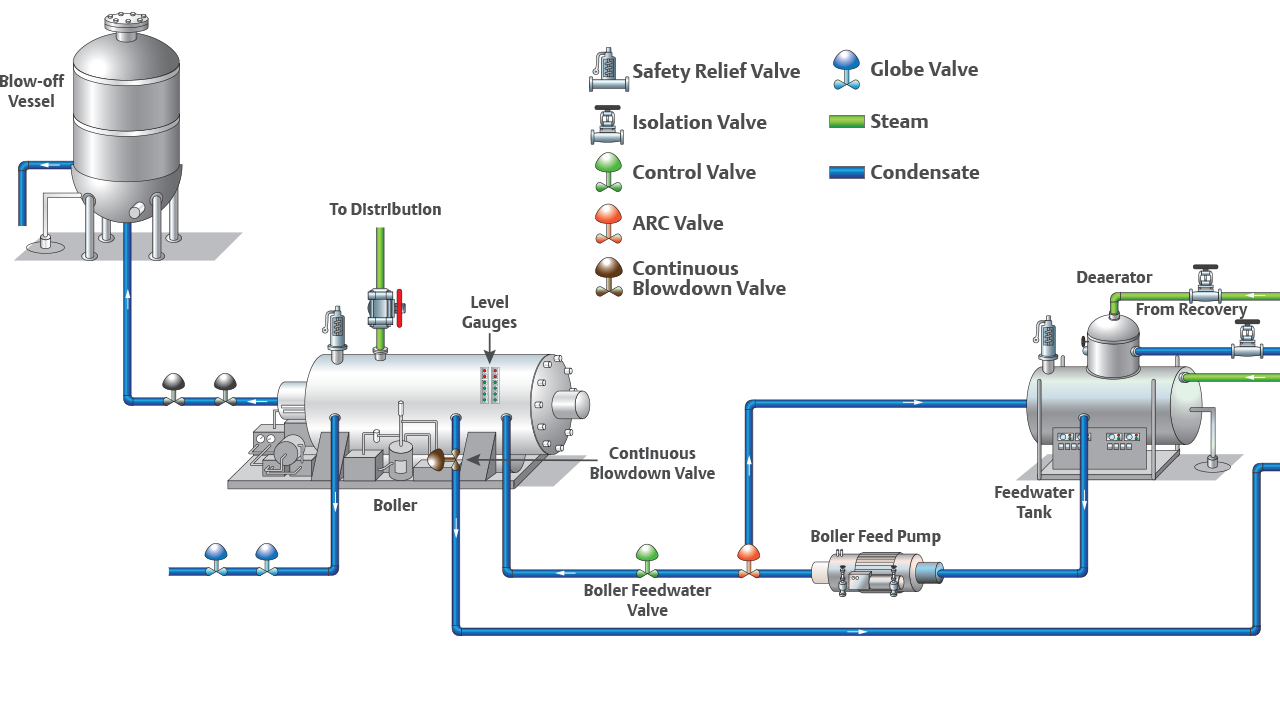

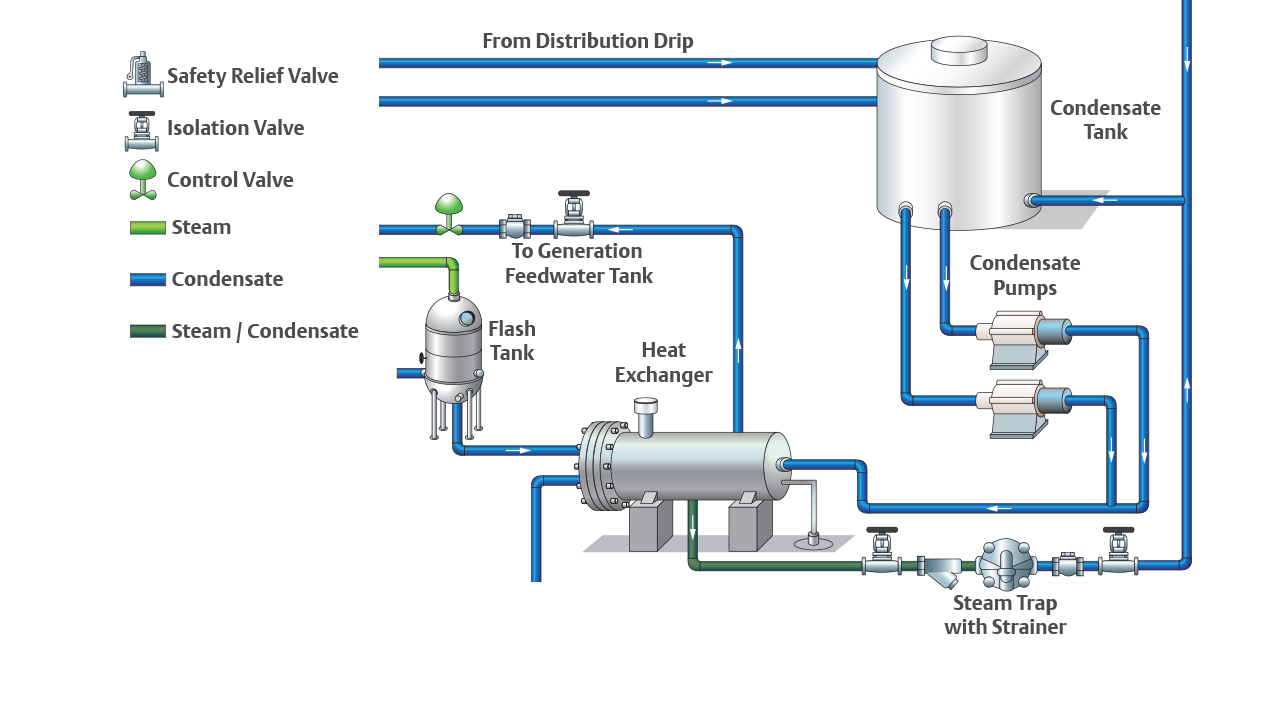

Web For this reason before inspection begins a map or some diagram of the location of all the steam traps and valves in a facility should be available.

. Why Manual valve is not used instead of steam trap. Steam trap with integral strainer c. This tutorial considers the operation and benefits of both types.

Applicable codes and standard for steam trap. Features required for an efficient steam trap. The trap operates by means of the dynamic effect of flash steam as it passes through the trap as depicted in Figure 1141.

All traps should be tagged and coded and referenced on the mapdiagram. Web Steam trap is a self contained valve which automatically drains the condensate from a steam containing enclosure while remaining tight to live steam or if allowing steam to flow at a controlled or adjusted rate. Steam traps vent air condensate and noncondensable gases from systems while trapping steam.

Install a strainer as part of the installation of a steam trap. They open close or modulate automatically. Basic Steam Trap Types.

Steam trap symbol in PID. They can continuously pass large volumes of condensate and are suitable for a wide range of process applications. Steam traps are nothing more than automatic valves.

Web Large vent 17 bar maximum Specification Inverted bucket steam trap type. Web A steam trap is a device used to discharge condensates and non-condensable gases with a negligible consumption or loss of live steam. This handbook provides a comprehensive guide for engineers operators and maintenance personnel who work with steam systems.

Install a blow down valve by connecting it to the. Contact Proficient Technologies Online Now. Depending on the methods the steam trap uses to differentiate between steam and the condensate steam traps can be divided into 4 different types.

Steam Trap Selection Chart. Purpose of steam trap in piping. Web STEP 1 - Where to Install the Thermostatic Steam Trap.

In addition the trap inventory should include the trap type size manufacturer and application. Web The diagrams and images shown on this document depict the piping arrangements of the standard range of Spirax Sarco pipeline connectors and traps. Mechanical steam traps How an inverted bucket steam trap works 1.

Most steam traps will also pass non-condensable gases while remaining tight to live steam. Web The thermodynamic trap is an extremely robust steam trap with a simple mode of operation. Types of steam trap.

17 20 13 9 5 1 3 7 11 15 8 4. How steam trap works. Maximum allowable back pressure 99 of inlet pressure.

Determine where to install the thermostatic steam trap based on the following information. As condensate reaches the trap it forms a waterseal inside the body. Web What is Steam Trap.

The strainer can be accomplished by the following. The weight of the. Web Steam traps are automatic valves that sense the difference between steam air condensate and noncondensable gases such as CO 2.

How to Order Specify. In addition the trap inventory should include the trap type size manufacturer and application. 15 17 812 34 IB1033-13-N-15 12.

Helping You Identify Implement Energy Saving Opportunities In Your Steam Systems. Web The thermostatic element expands when steam is present closing the trap and contracts when cooler air or condensate is present opening the trap which allows the condensate to drain. Web Trap TYPICAL PIPING DIAGRAMS Supply Inlet Valve Y Strainer Eye Hook Cover Bolts Dirt Pocket.

Web A proper functioning steam trap removes condensate and non-condensable gases without losing any live steam. Web Mechanical steam traps rely on the difference in density between steam and condensate in order to operate. The only moving part is the disc above the flat face inside the control chamber or cap.

Types include ball float and inverted bucket steam traps. The valve disc is disconnected from all other parts of the trap and rests on top of. NPT Code PSI lbs Armstrong 12.

In cast iron with continuous air venting at steam temperature free-floating stainless steel mechanism and discharge orifice at the top of the trap. Universal mount with an integral strainer The use of a strainer will eliminate or reduce premature failures of steam trap due to contamination. The 17C is cast bronze has a 25 psi maximum operating pressure and a capacity of 880 pounds per hour.

Web In a thermodynamic disc steam trap the flow of condensate is controlled by a circular shape valve head valve disc opening and closing against the valve seat. Ad The Best Steam Trap System Available. All traps should be tagged and coded and referenced on the mapdiagram.

Web Steam trap basics trap selection installation and maintenance best practices recommendations for common trapping and condensate return issues and other useful information that can help you reduce costs and save energy. Web 17 bar g Screwed FTGS14HC Horizontal Carbon steel 23 bar g Flanged FTC23 Horizontal 32 bar g Screwed Socket weld FTC32 FT450 Horizontal FTC32V Vertical down Flanged FTC32. The trap should be located below the equip-.

This prevents dirt from entering the trap. Web For this reason before inspection begins a map or some diagram of the location of all the steam traps and valves in a facility should be available. Web Industrial Steam Trapping Handbook - EmersonLearn the basics and benefits of steam trapping the different types and applications of steam traps and how to select install and maintain them.

The trap discharge should drain by gravity into. 2 Series C Pattern Trap Installations Install a Hoffman Specialty Y-strainer in the pipe ahead of the steam trap. Other special configurations can also be supplied to meet individual customer needs - consult Spirax Sarco.

1 The three important functions of steam traps are. Model PMO Weight Cross Ref.

The Inverted Bucket Steam Trap

What Is A Steam Trap Types Selection Features Codes Standards With Pdf What Is Piping

Sts17 2 Steam Trapping Station Spirax Sarco

Float And Thermostatic Steam Traps Watson Mcdaniel

Steam Basics Part 10 Understanding The Thermostatic Portion Of A F T Trap

Steam Trap Drawing Pdf Valve Steam

Steam Traps Watson Mcdaniel

Thermostatic Steam Traps Spirax Sarco

Steam Trap Pt17 Pennant Engineering Condensate Manual Heat Recovery

How Mechanical Traps Work A Look At Their Mechanism And Merits Tlv

Ta25b Radiator Steam Traps Watson Mcdaniel

Spirax Sarco 60587 2 Ftb 175 F T Steam Trap Cooney Brothers

Steam Trap Pt17 Pennant Engineering Condensate Manual Heat Recovery

Steam Traps Valves And Level Gauges Emerson Us

Steam Traps Watson Mcdaniel

Steam Traps Valves And Level Gauges Emerson Us

Steam Traps Watson Mcdaniel